Wishing to learn how to drill plexiglass? If you’ve ever tried it before, you know that there’s a right and a wrong way to drill plexiglass. If you aren’t sure about what you are doing, most likely you’ll end up with broken or melted plexiglass, and nobody wants that. This is exactly why we’ll be sharing with you all you need to know to make sure you know how to drill plexiglass.

Plexiglass represents a challenge because it can be prone to cracking or melting when it is drilled. You also should be aware that traditional drill bits and traditional drilling processes can cause damage to the plexiglass. In order to make sure you get a good result, there are key steps you must take during the drilling process; these steps will guarantee the success of your project.

As you can see, with the proper equipment and knowledge, you can rest assured that it will be easy to drill plexiglass. In this guide, you’ll find out everything you need to know to make sure your drilling process goes as smooth as possible. Continue reading as we share with you all the tips we know on how to drill plexiglass.

How to Drill Plexiglass FAQ’s

What is plexiglass?

Plexiglass, sometimes called transparent thermoplastic, acrylic, Lucite, and Perspex, is a polymer that is often used as an alternative to glass. It is valued for being shatter-resistant; plexiglass is used on construction projects that require durable, light plastic.

Is it difficutl to drill plexiglass?

Plexiglass can be brittle under certain forces and scratch easily, so it must be handled with care while you are working with it. There are a number of plexiglass-safe tools and techniques that can be used to avoid cracking or melting the material.

How do you drill a 1/2 inch hole in plexiglass?

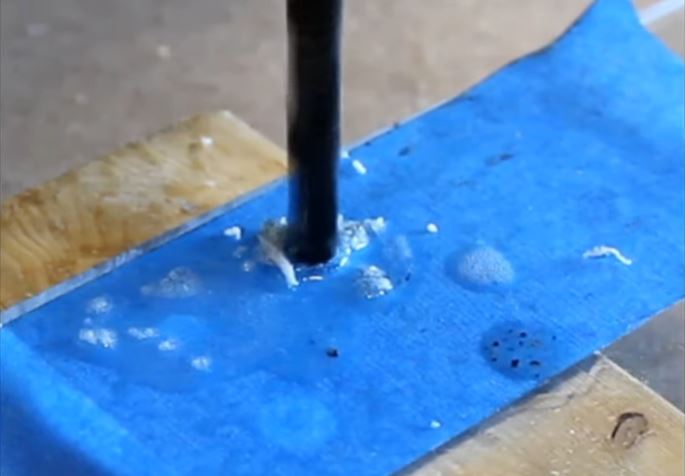

For example, to drill a 1/2 inch hole, you can make a pilot hole by beginning with a 1/4 bit drill and then moving to a 1/2 bit drill. While you are drilling through the plexiglass sheet, the friction would produce intense heat, and the bits would cause lots of plastic shavings around the hole, especially if the sheet is thick.

Can you use a regular drill bit for plexiglass?

Buy a plexiglass drill or plexiglass drill bits that can be used with a regular drill. These bits have a geometric structure designed to puncture acrylic more easily, and they are less likely to melt plexiglass. They are available in hardware stores and online.

Based on experiences from major experts, the special spiral bit has proved to be the best drill bit for drilling through sheets of plexiglass.

What kind of drill bit needs to be used to drill plexiglass?

Plastic Drill Bits: These are specifically made for plastic product drilling. They will not get as hot while you work and they shave and scrape out the hole rather than just drilling it straight through. This is a great solution if you want to avoid melting your plexiglass while you drill it.

Drill Bits for Plastic

Special Hi-Molybdenum tool steel, gold surface treated body, flute, and point for maximum lubricity.

Super CHIP FREE point is precision ground at a 60-degree angle for gradual penetration to avoid cracking and chipping of the acrylic material.

Protective Vinyl Pouches are conveniently marked with drill sizes, feed rates, and recommended RPMs. Excellent choice for handheld drill applications and a drill press or automated machines.

Features:

- High-Speed Steel

- Straight Shank

Modified Drill Bits: These drill bits are traditional drill bits that have been specifically designed or modified to work well on plexiglass. This modification will cause less grab as the drill bit is used, making it less likely to break or melt the plexiglass.

COMOWARE Titanium Twist Drill Bit Set

Classic HSS construction with titanium coating for capability and durability. The cutting edge is hardened and honed for sharpness; chatter-free design with staggered cutting teeth ensures precise countersinking and smooth-clean holes.

Two flutes form helps clear chips and debris away from the bit, decreasing friction and heat for a faster, cooler drilling process.

1/4 inch hex shank fits into all power tools more easily and securely, especially for locking into the quick-change chuck.

Features:

- High-Speed Steel

- Titanium

Diamond Dusted Drill Bits: These bits are made to drill through hard or thick plastics. The drill bit has diamond dust coated on the exterior of its cutting surfaces, making it stay sharp and making it less likely to break or crack the plexiglass as you work. They can run hotter than a regular bit, so slow drill speeds are suggested to prevent melting.

Multi-Material Drill Bit Set

One drill bit replaces two drill bits (1x glass & tile drill bit + 1x Masonry drill bit), ideal for drilling fastener holes in bathroom tiles or wall mirrors.

Once it drills through the tile or mirror, this drill bit will cope easily with any masonry behind it.

U type slot design with fast drilling dust remove, 3-flats shank allows the drill bit to be held tightly and stably in a power drill. When drilling hard material (glass, porcelain floor tile, marble or granite), please use water for lubrication.

Features:

- Carbide

- 3-Flat Shank

- Spiral Flute

Can you drill into scrap plexiglass?

Practice with smaller pieces of scrap acrylic before drilling into a large sheet. Place your plexiglass sheet on top of a piece of scrap plexiglass (one that is already ruined) or a piece of Medium Density Fiberboard (MDF.)

What you should know before drilling plexiglass?

- Because plexiglass can be brittle and shatter, you must always wear a mask and safety glasses when you are drilling into it. Dust and other debris from plexiglass can be quite sharp and injure your eyes or lungs.

- It would help if you always had safety glasses on when you are drilling into any surface, but plexiglass is one of the materials that you cannot afford to be casual about working with.

- always have safety glasses on when you are drilling into any surface, but plexiglass is one of the materials that you cannot afford to be casual about working with.

How to Drill Plexiglass

Have your tools ready

- You want to make sure your equipment is readily available, especially the plexiglass drill and bits. Here, you have to ensure that the drill bits you are planning to use are reliable and won’t cause any deformation to the plexiglass.

- The materials or items needed for drilling through plexiglass are safety goggles, clamps and clamping strip, screw clamps, cloth or napkin, drill stand, wooden base, plexiglass drill bits or acrylic drill bits, medium-density fiberboard (MDF), stop angle, countersink, metal/plastic file, draw the blade and the plexiglass that needs drilling.

Prepare your working area.

- Put your sheet of plexiglass on a flat surface. It can bend slightly if you try to hold it and drill, and the added flex of the material can lead to cracks or can even break the plexiglass. You can also check out a flexible drill bit.

- You might not be able to see that the sheet is bending, but the internal structure of the sheet of plexiglass can be affected.

Clamping the sheets

- Use another sheet of ruined plexiglass or a medium-density fiberboard under your plexiglass that needs to be drilled.

- You can use clamps to attach the two sheets to one another. This protects the backside of the sheet of plexiglass from showing damage or roughness when you are done drilling.

- You can also drill holes in all kinds of glass with a Dremel if you have one.

Power your drill, set the speed, and start drilling

- The next step after clamping both sheets is to power your drill and start drilling. If your drill is an electrically operated one, switch on the plug on the wall socket and ensure power gets distributed down to the engine of the drill.

- Be aware that if you need to drill at the edge of the sheet of plexiglass, it will be more likely to break or crack. You should work very slowly if you are placing holes near the edge of the sheet.

- No matter where the hole is located, you will need to start very slowly and create a dimple or divot to mark the spot where your hole will be. Or, you could opt to drill a pilot hole.

- The whole drilling process begins, and you start to drill slowly through the sheets of the plexiglass. Since you are dealing with glass, a fragile object, you should exert less pressure on it.

Keep a smooth and steady pace.

- Maintain the steady, slow pace and keep going at a feed rate of about 3.5 inches. In that process, some tiny bits of glass particles will occasionally accumulate and surround the tip of the drill bit, take regular breaks and remove these particles to have a better view of the drilling process.

- You will need to be smooth and steady as you drill this kind of hole. Plexiglass can catch or grab the drill bit, so you cannot run the drill bit in and out quickly as you would with a wooden surface, or you will break the plexiglass.

- Slow and steady is the name of the game, and you should plan to press down in one smooth motion to the depth that is required.

- Always make sure that you check the temperature of the drill bit when you have drilled the first pass through the hole. If it is hot at this point, let it rest and cool down.

How to Drill Plexiglass Video

What to do if your sheet of plexiglass is thick?

- If you are trying to drill through a thick sheet of plexiglass and feel like the drill is just grabbing the material and not going through smoothly, you can switch to a smaller and sharper drill bit and make a series of small holes around the center mark that you have made.

- This is called peck drilling, and it can be a great way to get a hole started when you are dealing with thick materials.

- Make sure to let the drill rest and cool off in between each hole that you drill so that you do not melt the plexiglass.

- You will be able to blend the small circles of the hole when you are done by drilling a central hole with this smaller drill bit. You can then use a larger drill bit for deburring and cleaning up the edges of your peck-drilled hole.

- This is a great trick to prevent damage to the plexiglass that would potentially shatter or crack it, and it is much easier on your tools and equipment as you work.

How to Drill Plexiglass Additional Tips

- Depending on the drill you are using, plug it in or put in the charged battery and turn it on.

- To drill plexiglass, unlike how you bore a hole through metals or stones, you don’t have to puncture the plexiglass; begin to pierce the marked spots slowly.

- Don’t push too hard; you can aim at a speed of 3.5 inches per minute.

- For cleaner holes, stop the drilling as soon as you puncture the opposite side, un-clamp the sheet, turn it over and drill through the other side in the same place.

- It is possible to drill acrylic with regular metal drill bits; however, the likelihood of melting, chipping, cracking, or breaking the acrylic is much higher. Ensure you go slow, often stop to cool the drill, and always support the sheet.

- For clean works, you should set it to a low rotational speed; otherwise, you should consider the diameter of the hole to be drilled because of the more significant the diameter of the hole, the lower the rotational speed of the drill bit.